Researchers from the RIKEN CENTER FOR EMERGENT SCIENCES(CEMS) led by Takuzo Aida have developed a biodegradable plastic that will dissolve in seawater. Leading to the invention of a new sustainable material that solves the microplastics pollution problem in oceans and soil.

The problem with current biodegradable plastics

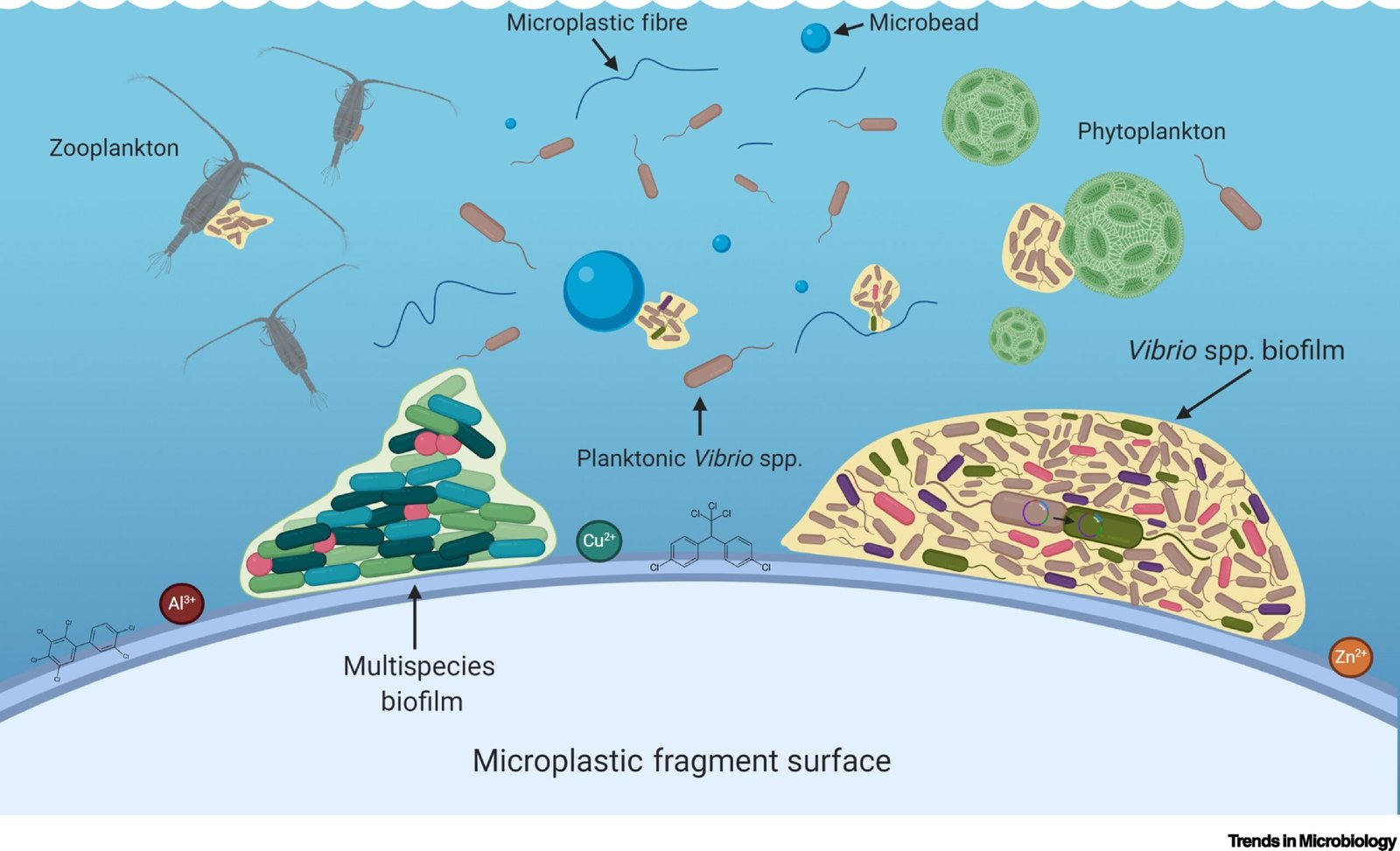

Current biodegradable plastics like PLA often end up in water bodies and they cannot biodegrade since they are non-soluble in water. As such, microplastics- plastics that are less than 5mm – are finding their way into oceans and aquatic life. Microplastics interfere with the food chain and can end up in human bodies when we consume fish or other aquatic life.

The Innovative Solution: Supramolecular Plastics

Supramolecular plastics are polymers with structures held together by reversible reactions. The biodegradable plastic was made by combining two ionic monomers – sodium hexametaphosphate and guanidinium ion-based monomers that form cross linked salt bridges. Sodium hexametaphosphate is a common food additive. Both monomers can be broken down by bacteria, thus making the plastic biodegradable as it is broken down into its components, leaving us with a sustainable material.

In the new biodegradable plastic, the salt bridges structure is irreversible and only breaks down when exposed to electrolytes found in sea water.

How the Plastic Is Made: The Desalting Step

The two monomers are mixed together in water resulting in two separate liquuids. One was thick and viscous, containing the structural cross-linked salt bridges while the other was watery and contained salt ions. When sodium hexametaphosphate and alkyl diguanidinium sulfate were mixed, sodium sulphate salt was produced in the watery layer. The resulting plastic, alkyl SP2, was made by drying the remains of the thick viscous liquid.

The resulting material remained as a brittle crystal, not ideal for use as plastics. But this was overcome by an innovative desalting process. Resalting the plastic in salt water caused the interactions to reverse and the plastic’s structure broke down within a few hours. Thus creating a strong and durable plastic that was biodegradable under certain conditions.

Qualities of the biodegradable plastic

The plastic is non-toxic and non-flammable, it does not release any CO2 into the environment. It is flexible and malleable, which can be reshaped like other thermoplastics. The biodegradable plastic can be transformed into hard scratched resistant plastics, rubber silicone-like plastics, strong weight bearing plastics or low tensile flexible plastics. The plastics can be used in 3D printing as well as various healthcare needs.

Environmental Impact and Benefits

By dissolving the plastic in salt water, the scientists were able to recover 91% hexametaphosphate and 82% of the guanidinium as powders. This means that it is easy and efficient to recycle. When left in soil, the plastic completely biodegraded within 10 days and providing the soil with phosphorous and nitrogen, similar to that of fertilizers. The biodegradable plastic also eliminates microplastics from the environment, giving us a sustainable material that solves the microplastics problem.